You can either dismantle all the plate and frame heat exchanger OR you do the chemical cleaning. Well, i can say the decision must be correct. You must decide which method to chose.

If you decide to dismantle the heat exchanger and heat exchanger tubes, this will give you the highest cost impact. Why? This is because, when you dismantle the plate & frame heat exchanger, the gaskets in between the plates cannot be used anymore. Once the heat exchanger is opened, it can't be used again. The polymer structure of the gasket has already be distorted and is not in a prefect condition to be used again. By the time you open the heat exchanger, some of the gasket, might also be damaged too. Some of them have became very thin. Some of them have been torn. There are many types of condition. And most of the time, oil leaks in the heat exchanger is due to the gasket problem or the operator/technician did not fix the gasket properly on plate heat exchanger.

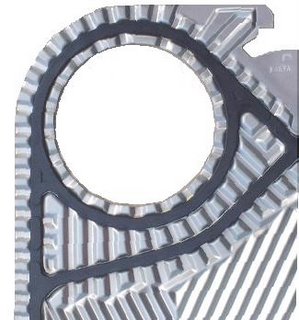

Example of a gasket to be placed in between the heat exchanger plates

A cleared picture of how the gasket is inserted and attached to the plates

One set of gasket to be placed in between two plates is very expansive. Depending on what type of heat exchanger, type of plates, type of oils/fluids flowing, and also range of operating temperature. This information can be obtain from a gasket or heat exchanger supplier/manufacturer. So, imagine if the plate and frame heat exchanger have 220 plates, you must have 221 gaskets placed in between the plates and the two stainless steel frames on both ends.